| Filling method |

Auger weighing filling |

| Tank size |

Diameter φ50-180mm, height 50-350mm |

| Filling range |

10-2000g |

| Filling speed |

0-20 cans / min |

| Power |

Three-phase 380V (or single-phase 220V),3.5kw |

| Machine weight |

1000kg |

| Container size |

Diameter 50--180mm, height 50--350mm |

| Machine dimension |

3330 × 1400 × 2400mm |

| Hopper volume |

50L |

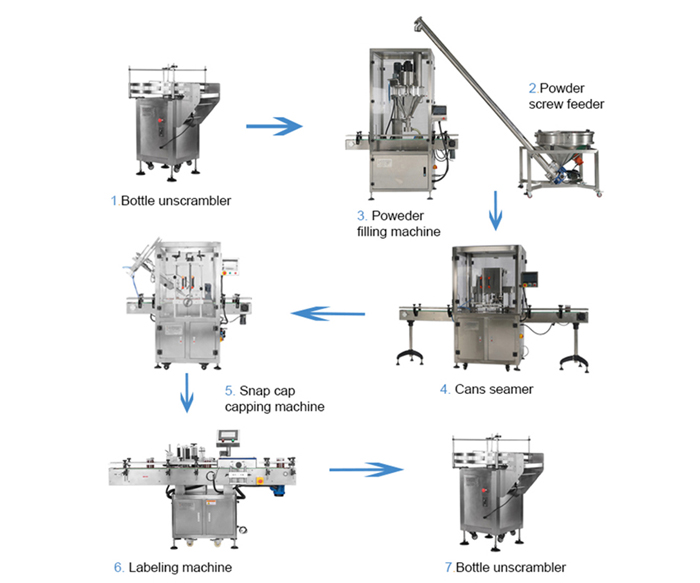

MILK POWDER PACKAGING LINE IN DETAILS

Sealing Machine With Vacuuming And Nitrogen filling High Speed Sealing Machine

Automatic vacuumize and nitrogen filling, automatic sealing Automatic sealing cans with high speed

.jpg)

Bottle Flip Blowing Sterilizing machine Can/Bottle Surface Cleaning Machine

This machine is a conveying sterilization equipment can thoroughly This machine is a cleaning equipment for the surface of finished cans

disinfect the top and the bottom of the can in an all-round way

Description:

Description:

1. The automatic powder filling line includes: bottle unscrambler → automatic feeding machine → single-head powder filling machine → capping machine (or can sealing machine) → bottle mouth aluminum foil sealing machine → labeling machine → inkjet printer → Chain conveyor belt→packing platform, the assembly line configuration can be selected according to the requirements of the customer.

2. The appearance of the whole set of machines in this production line is all stainless steel, and all machine structures are selected and designed in accordance with food and drug hygiene standards;

3. The inner wall of the container in contact with the material is polished, and the structure that is frequently disassembled and washed is connected with easy-disassembled parts to ensure that it is hygienic and convenient to handle when shifting or changing products;

4. You can go to the factory for site survey and design the best production plan on the spot; provide free technical support for other aspects of the production line.

Shipping&Delivery:

.jpg)