What problems does the automatic packaging machine resolve for the enterprise?

Feb 19, 2022

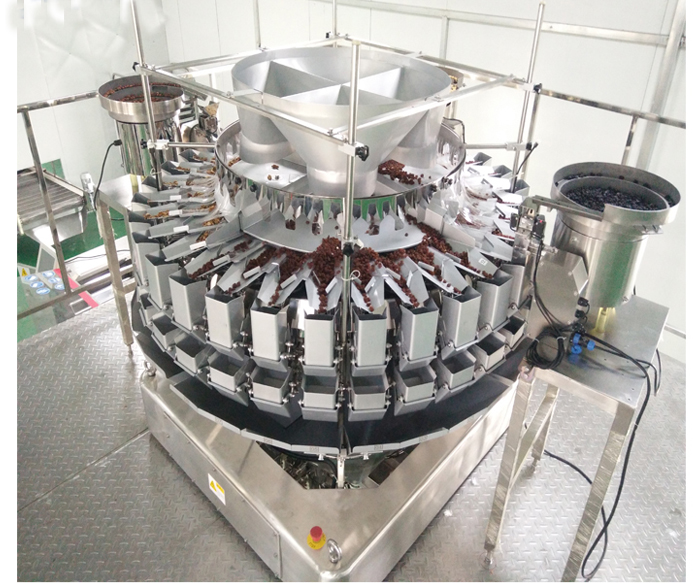

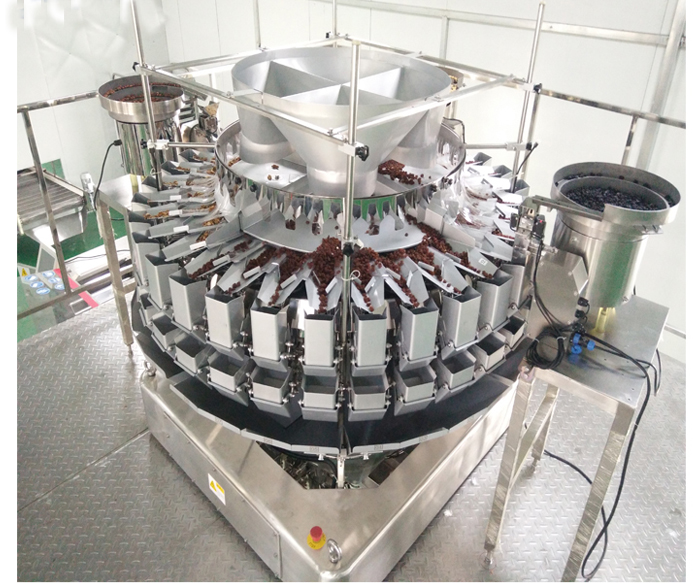

1. High efficiency

In the past, the production efficiency of traditional manual packaging was relatively slow and it was easy to lose materials. Using a fully automatic packaging machine instead of manual packaging can efficiently complete the production process of feeding, measuring, bagging, printing date, and product output. This mechanized assembly line brought high metering accuracy, fast efficiency, saves materials and reduces labor costs.

2. Reduce labor intensity

The automatic packaging machine replaces manual packaging and frees workers from heavy work. Like some small-sized products, manual packaging is labor-intensive and not easy to package; secondly, some products will produce dust, radioactive, irritating and toxic hazards during the production process. The packaging machine can solve these problems.

3. Energy saving and environmental protection

Generally, the automatic packaging machine with good service has the function of automatic detection. Therefore, for those products that are not qualified, the machine can intelligently screen and repackage them again, which improves the qualification rate and does not waste materials. It is also easy to maintain and operate, which greatly reduces production costs.

4. Safety and health

Manual packaging is difficult to avoid contact between people and production products due to manual participation, which may contaminate products and make it difficult to guarantee production quality. The automatic packaging machine has no manual participation from feeding materials to the automatic production of finished products. This packaging production line reduces bacterial contamination in the packaging process and provides a good guarantee for the enterprise.

In the past, the production efficiency of traditional manual packaging was relatively slow and it was easy to lose materials. Using a fully automatic packaging machine instead of manual packaging can efficiently complete the production process of feeding, measuring, bagging, printing date, and product output. This mechanized assembly line brought high metering accuracy, fast efficiency, saves materials and reduces labor costs.

2. Reduce labor intensity

The automatic packaging machine replaces manual packaging and frees workers from heavy work. Like some small-sized products, manual packaging is labor-intensive and not easy to package; secondly, some products will produce dust, radioactive, irritating and toxic hazards during the production process. The packaging machine can solve these problems.

3. Energy saving and environmental protection

Generally, the automatic packaging machine with good service has the function of automatic detection. Therefore, for those products that are not qualified, the machine can intelligently screen and repackage them again, which improves the qualification rate and does not waste materials. It is also easy to maintain and operate, which greatly reduces production costs.

4. Safety and health

Manual packaging is difficult to avoid contact between people and production products due to manual participation, which may contaminate products and make it difficult to guarantee production quality. The automatic packaging machine has no manual participation from feeding materials to the automatic production of finished products. This packaging production line reduces bacterial contamination in the packaging process and provides a good guarantee for the enterprise.

Share:

Contact us