Features Of Automatic Powder Filling Machine Production Line

May 18, 2021

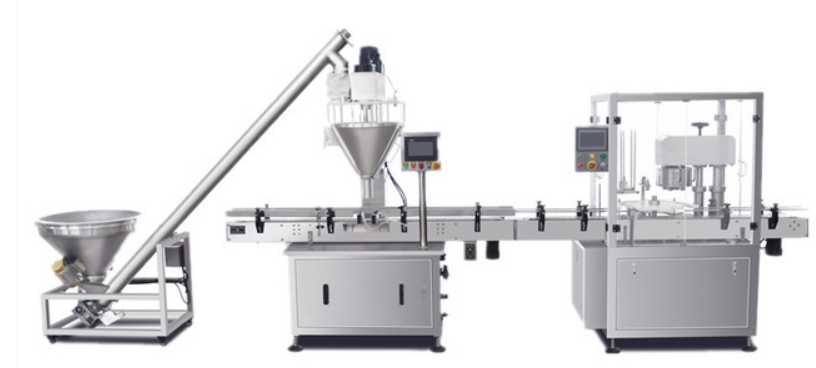

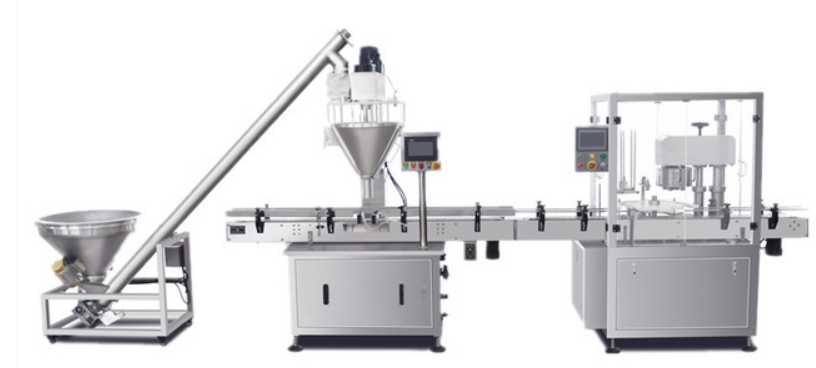

The whole machine design of the automatic powder filling machine production line is reasonable, the packaging varieties can be changed, and the cleaning is extremely convenient. The automatic powder filling machine is controlled by PLC, which is anti-interference and stable in work. Touch screen display, the screen displays multi languages working status and operation instructions, which is simple and intuitive, the packaging weight is steplessly adjustable, the operation mode can be changed at will, and the fault alarm prompts. The filling of the automatic powder filling machine equipment production line is driven by servo motor, with high positioning accuracy, high precision, large torque, long life, and adjustable speed. The mixing adopts Taiwanese maintenance-free motors. The automatic powder filling machine adopts screw filling machine for filling, adopts servo, indexing disc positioning system, touch screen display, PLC control, and the packaging accuracy and speed are improved. It is suitable for packaging various powdery and ultra-fine powder materials.

Automatic powder filling machine production line packaging process:

Bottle unscramble→filling bottle, capping (including: the size of the bottle is matched with the size of the turntable, and the weight setting is mainly measured by the number of screw rotations)→the screw feeder feeds the screw to the screw metering machine and stirs→screw metering→filling Powder → screw cap → turntable rotation output → workbench. The patented screw can solve the dust problem during the filling process. The automatic powder filling machine can replace the screw attachment, and can be adapted to the packaging of large particles to ultra-fine powder materials. According to different materials, it can be equipped with vacuum negative pressure, vibration and other devices. Various product parameter formulas can be stored and can be recalled at any time.

Automatic powder filling machine production line packaging process:

Bottle unscramble→filling bottle, capping (including: the size of the bottle is matched with the size of the turntable, and the weight setting is mainly measured by the number of screw rotations)→the screw feeder feeds the screw to the screw metering machine and stirs→screw metering→filling Powder → screw cap → turntable rotation output → workbench. The patented screw can solve the dust problem during the filling process. The automatic powder filling machine can replace the screw attachment, and can be adapted to the packaging of large particles to ultra-fine powder materials. According to different materials, it can be equipped with vacuum negative pressure, vibration and other devices. Various product parameter formulas can be stored and can be recalled at any time.

Share:

Contact us